| Project Name: |

|

|

Polyester Polymerization Lines , Polyester chip plant,Polyester production plant , Polycondensation plant (Polytex tech,Polytex Design)

Main Raw Material: PTA(Pure Terephthalic Acid) and MEG (Mono Ethylene Glycol) OR DMT(Dimethyl terephthalate) and MEG (Mono Ethylene Glycol)

|

|

| Project Description: |

|

|

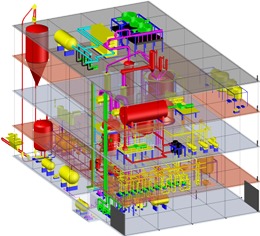

PET batch type,PTA or DMT based (BP)(Single line:2TPD¡«100TPD)

PET continuous polymerization,PTA based (CP)(Single line:20TPD¡«1000TPD)

Mult-Function continuous polymerization,PTA or DMT based (M-CP)(Single line:15TPD¡«300TPD)

|

|

| Polyester batch type (Polytex tech,Polytex Design) (Batch-poly Single line:2TPD¡«100TPD): |

|

|

EG distribution system

Paste preparation system

Esterification system

Polycondensation system

Chip cutting and packing system

TiO2/SiO2 Preparation System

Filter cleaning system

EG recovery system

Other Additative (Including SIPE/SIPA)Preparation System

Thermal Fluid system

DCS/PLC

|

|

|

|

| Specification and Advantage: |

|

|

Paste preparation system can be used for preparing material of modified PET, catalyst and additive can be fed in low temperature.

Esterification in the low-temperature normal temperature or under continuous feed, easy to control, safe and reliable

The Pre-poly reactor is for modified PET products. It's easy for changing product, and the reactor should not be cleaned to avoid the material waste caused by system start and stop. Pre-poly reaction can be finished to improve the product capacity.

EG vacuum system will not generate the waste water.

|

|

|

Apply to Bright chips,Alkali-dissolved chips, CDP, Semi-dull, Full- dull, Antistatic, Anti-pilling, Far infrared, Antibiosis, Film grade, Bottle grade and other fields. |

|

| |

|

|

|

| |

|

|

|

| |

|

| Polyester continuous polymerization (Polytex tech,Polytex Design)(CP Single line:20TPD¡«1000TPD): |

|

| |

|

|

EG distribution system

Paste preparation system

Esterifing reaction system

Prepolycondensation reaction system

Pre-polymerize filter system

Final polycondensation reaction system(DRR)

Melt filteration and distribution system

Chip cutting,conveying and packing system

TiO2/SIPA/SIPE/SiO2/Toner/.. preparation system

Catalyst preparation system

Energy saving system

Thermal Fluid system

DCS

|

|

| Specification and Advantage: |

|

|

Low temperature, low mol-ratio, tender reaction

Most reasonable Residence time distribution

Most reasonable plug-flow effect to keep the material even on different period

Low material and public utility consumption, excellent economical

Own Know-how and Manufacturing

Low DEG and oligmer content

Melt with excellent flowing ability and spinnablity

Comprehensive running costs are highly competitive

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

|

|

Single line:20T/D¡«1000T/D,Since 2002,Polytex has successfully launched a lot of different grades of CP projects.

Widely used in textile (Direct melt spinning/staple fiber/non-woven, etc.,), Film grade, Bottle grade, Industrial yarn and other industries . |

|

| |

|

| Mult-Function continuous polymerization(Polytex tech,Polytex Design)(M-CP Single line:15TPD¡«300TPD): |

|

|

ECDP,CDP,PETG,Water-soluble,low-melting and other special CP production lines have successfully run in the world.

Different products can be produced, and the loss for changing product is less

Unique process technology, perfect combination of batch and continuous process

Output can be adjusted by the requirements, range: 50%-130%

Stable product quality, even polyester melt, decrease intermediate steps

Reliable automation control, not only assure the product quality, but also easily operation

With excellent performance and price ratio, low investment, high respond

Suitable for direct spinning/Non-woven..

|

|

|

|

| |

|

|

|

| |

|

Single line:15T/D¡«300T/D

Apply to Bright chips,Alkali-dissolved chips,ECDP(Easy Cation-Dyeable Polyester),CDP,Semi-dull,Full- dull,Antistatic,Anti-pilling,Far infrared, Antibiosis,Film grade,Bottle grade,Directly spinning fiber, Staple fiber,Film,SSP and other fields. |

|

| |

|

|

The polyester CP undertaken by POLYTEX can be operated for a long time under a load of 65% to 130%. It has the advantages of low temperature, low energy consumption, low molar ratio, flexibility, and functionality.

Safe, stable and easy to control are the main features of the POLYTEX project.

Integrated production costs very competitive advantage for our customers in the market competition in the industry and be able to obtain long-term advantage.

Performance for many potential customers reference, including: polyester bottle grade, film grade polyester, polyester fiber grade polyester and other specialty products, welcome customers to visit polytex.

Ningbo Dafa-750 TPD PET TO LOW MELT PSF,FUWEIER-750 TPD PET TO LOW MELT PSF,Ningbo Huaxing-750 TPD PET TO LOW MELT PSF,JIXING-1000 TPD PET TO PSF

INDIA-600TPD PET DIRECT TO FILM,EP NEW MATERIAL 2X1000TPD BOTTLE GRADE PET,HUABAO 2x500TPD PET TO POY

Turkiye-RBK 840TPD PET DIRECT TO POY/FDY GENERAL CONTRACTOR

More Than 10 lines(Single line capacity from 60 TPD TO 600 TPD),for PETG/CDP/ECDP/Low melt/Low viscosity/Low Endgroup

|

|

All inquire welcome be send to Email: market@polytex.cc ¡¡ polytex@vip.sohu.com

|