| Project Name: |

|

|

PBT Polymerization Lines , PBT chip plant,PBT production plant , Polycondensation plant (Polytex tech,Polytex Design)

Main Raw Material:PTA(Pure Terephthalic Acid) and BDO (1,4-butanediol) or DMT(Dimethyl terephthalate) and BDO(1,4-butanediol)

|

|

| Project Description: |

|

|

PBT batch type,PTA or DMT based (BP)(Single line:2TPD゛100TPD)

PBT continuous polymerization,PTA based (CP)(Single line:20TPD゛500TPD)

|

|

| PBT batch process(Polytex tech,Polytex Design) (Batch-poly,Single line:2TPD゛100TPD): |

|

|

BDO distribution system

Paste preparation system

Esterification system

Polycondensation system

Chip cutting and packing system

Catalyst Preparation system

Filter cleaning system

THF recovery system(99.99%)

Other Additative Preparation System

Thermal Fluid system

DCS/PLC

|

|

| Specification and Advantage:

Slurry preparation system used for modified PBT, catalysts and additives can be added at low temperatures

Esterification in the low-temperature normal temperature or under continuous feed, easy to control, safe and reliable

BDO vacuum system will not generate the waste water.

Apply to Bright chips,film chips,textile grade,Engineering plastics chips,etc.,

|

|

|

| |

|

| PBT continuous process (Polytex tech,Polytex Design)(Single line:20TPD゛500TPD)

|

|

| |

|

|

BDO distribution system

Paste preparation system

Esterification system

Pre-Polycondensation system

Pre-Poly filter system

Final-Polycondensation system(special)

Melt transfer & Polymer filter system

Chip cutting and packing system

Catalyst Preparation system

THF recovery system (99.99%)

Other Additative Preparation System

Thermal Fluid system

DCS

|

|

|

Specification and Advantage:

Low temperature, low mol-ratio, tender reaction

Most reasonable stay-time distribution

Most reasonable plug-flow effect to keep the material even on different period

Low material and utility consumption, excellent economical

Own Know-how and Manufacturing

Melt with excellent flowing ability and spinnablity

Comprehensive running costs are highly competitive

Different structure reactors for modified PBT with different Design

|

|

|

|

|

|

Single line:20T/D゛500T/D,Till 2018,Polytex has successfully launched different grades of PBT projects.

Widely used in textile (Direct melt spinning), Film grade, Engineering plastics and other industries . |

|

| |

|

|

The PBT CP undertaken by POLYTEX can be operated for a long time under a load of 50% to 120%. It has the advantages of low temperature, low energy consumption, low molar ratio, flexibility, and functionality.

Safe, stable and easy to control are the main features of the POLYTEX project.

PBT Direct Melt To Spinning is the main know-how of the POLYTEX.

Integrated production costs very competitive advantage for our customers in the market competition in the industry and be able to obtain long-term advantage.

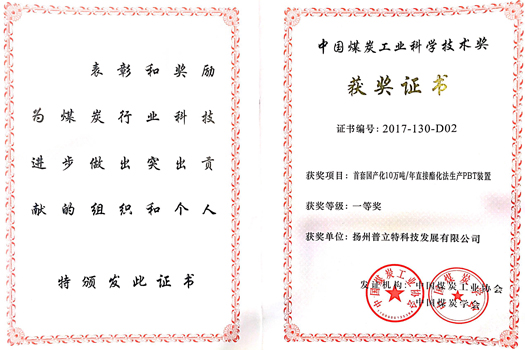

Henan Kaixiang 400TPD continuous PBT project consists of the contracted of POLYTEX is the large capacity, win first prize in Henan Science and Technology Commission of Science and Technology and the China Coal Industry Association of Science and Technology award.

The modified PBT (part of the performance-replaceable spandex) plant in Zhejiang Jiaxing, which was constructed by POLYTEX, has been verified so far and will enter industrial production soon.

Performance for many potential customers reference, including:film grade, fiber grade, Engineering plastics and other specialty products, welcome customers to visit polytex.

|

|

|

LASTED NEWS:

M/S Ningbo Meiyuan 400TPD PBT PROJECT, which was EPC by POLYTEX,successful commissioning in 13.Dec 2019.The IV value was from 0.75 to 1.32 in Meiyuan PBT project

Multiple sets of single-line 200-400TPD PBT CP LINES are in progress...

The modified PBT (PBAT) with capacity 600TPD CP LINES are in progress...

|

|

All inquire welcome be send to Email: market@polytex.cc polytex@vip.sohu.com

|