| Project Name: |

|

|

Pa6-Project (Polytex tech,Polytex Design)

Main route:The caprolactam monomer is hydrolyzed at a high temperature to obtain aminocaproic acid, and then polymerized at a high temperature to obtain nylon 6.

|

|

| Project Description: |

|

|

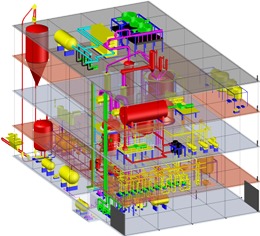

Pa6 batch type (Single line:5TPD~30TPD)

Pa6 continuous polymerization(Single line:15TPD~120TPD)

|

|

|

Caprolactam melting system

Pre-Polycondensation system

Polycondensation system

Chip cutting system

Extraction

Nitrogen refining

Continuous drying

Packing system

Thermal Fluid system

DCS

|

|

|

|

| Advantage: |

|

|

Polymer tube static mixing technology

Oligomer extraction technology

The concentrate recovered by three-effect evaporation is directly reused by high pressure cracking.

(Cooperated with domestic experts to launch the Pa6 direct-spinning)

|

|

|

|

| |

|

|

|

| |

|

| Pa66-Project Description: |

|

|

Pa66-Project (Polytex tech,Polytex Design)

Main route:The Nylon 66 salt formed by using hexamethylenediamine (HMD) and adipic acid (ADA) as a raw material is polycondensed under high temperature and high pressure to obtain Nylon 66 polymer.

|

|

| Project Description: |

|

|

Pa66 batch type (Single line:5TPD~30TPD)

Pa66 continuous polymerization(Single line:15TPD~120TPD)

|

|

|

Salt formation system

Salt solution preparation system

Salt liquid concentration system

Salt prepolymerization system

Vacuum flashing system

Precondensation reaction system

Final-polycondensation reaction system

Melt transfer system

Chip cutting and packing system

Additative Preparation system

TiO2 Preparation system

Catalyst Preparation system

Exhaust gas washing system

Thermal Fluid system

DCS

|

|

| Advantage: |

|

|

Multiple temperature and pressure precise control strategies

Most reasonable stay-time distribution

Most reasonable plug-flow effect to keep the material even on different period

Low material and utility consumption, excellent economical

Own Know-how and Manufacturing

Special anti-coagulation design, replacement cycle is better than existing process

Different structure reactors for different Products

Comprehensive running costs are highly competitive

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

|

|

|

The Nylon6/66 project undertaken by POLYTEX can be operated for a long time under a load of 50% to 120%. It has the advantages of low temperature, low energy consumption, low molar ratio, flexibility, and functionality.

Safe, stable and easy to control are the main features of the POLYTEX project.

Integrated production costs very competitive advantage for our customers in the market competition in the industry and be able to obtain long-term advantage.

Performance for many potential customers reference, including specialty products, welcome customers to visit polytex.

|

|

All inquire welcome be send to Email: market@polytex.cc polytex@vip.sohu.com

|